In the domain of industrial operations, preserving the integrity and performance of pipelines is critical. Assembling of residue within pipes can substantially thwart fluid dynamics, degrade product quality, and amplifies upkeep expenses. To tackle these predicaments, channel scrubbing procedures have developed as exceptionally capable fixes for smooth pipeline sanitation. A contraption, usually a circular mechanism, is propelled through the passage, adroitly cleaning accumulations and ensuring ultimate output

Duct washing procedures deliver myriad pros. They are adaptable, equipped for sanitizing conduits of divergent dimensions and components. Furthermore, they are potent, executing the function in a moderately rapid duration. By trimming downtime and enriching pipeline efficiency, pipeline cleaning systems advance economic benefits and boosted operational work

Cleanliness Pipeline Practices:

Upholding pipeline uncontaminated status is essential for warranting goods protection and value of delivered goods. Sanitary pigging strategies deliver a steady way to reach this purpose. Pigs, particular tools, are put in into pipelines to sanitize by taking out residues and pollutants

- Multiple categories of sanitary pigs are available, each created for particular cleaning duties.

- These pigs are crafted from substances that conform to stringent decontaminated standards.

- Periodic sanitary pigging functions help warding off product deterioration, prolong pipeline stability, and strengthen overall productivity.

Next-Generation Pigging Applications for Peak Effectiveness

Amid the territory of passage upkeep, leading pigging techniques have surfaced as a major tool for ensuring superior effectiveness and shielding. These leading-edge systems take advantage of ingenious designs and features to efficiently sanitize, check, and defend ducts from wear. From advanced pigs provided with live analysis tools to designed pigging apparatus purposed for sophisticated tasks, improvement in this sector is unceasingly extending scope. By implementing these breakthroughs, managers can greatly enhance pipeline sturdiness, lower downtime, and heighten operational capability.

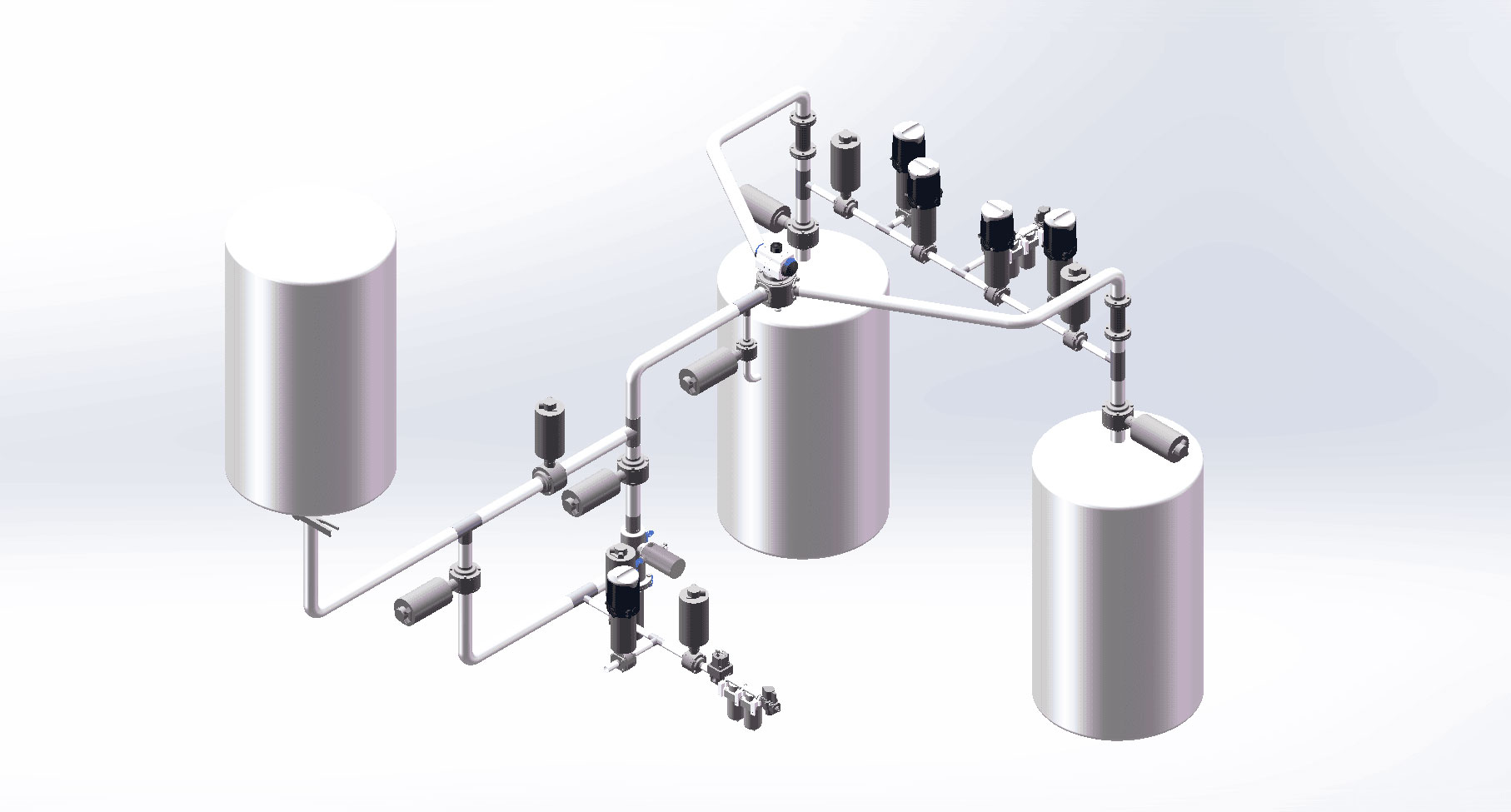

All-inclusive Pigging Arrangement Development and Setup

A comprehensive pigging system incorporates a pivotal procedure for pipeline service. This procedure requires the integration of designed instruments called pigs, which move through pipelines to wash, assess, and maintain their integrity. The configuration underscores features such as conduit scale, content, pig class, and operational demands. A efficiently conceived system ensures productive pigging missions while lessening downtime and potential harms. Installation customs impose careful arrangement, skilled engineers, and strict adherence to safety protocols to guarantee a sure and productive result

Engineering Pigging Devices for Broad Operations

Manufacturing pigging gadgets are essential instruments deployed across a broad set of industries. These tools advance protected and optimal washing, scrutiny, and preservation of pipes and other pipe-like buildings. Pigging requires sending constructed apparatuses known as pigs through pipes to perform a variety of tasks. Frequently Used types of industrial pigging gadgets consist of cleaning pigs, inspection pigs, and shipment pigs. Cleaning pigs are engineered to displace debris, build-up, and defilements from pipelines. Inspection pigs are equipped with gadgets that harvest information about the condition of pipe linings. Transport pigs are operated to carry materials through pipelines. The use of industrial pigging products furnishes numerous positive effects, such as lessened downtime, heightened pipeline sturdiness, and raised operational effectiveness. These systems are extensively applied in fields such as oil and gas, water treatment, chemical production, and food manufacturing.Extensive Pipeline Pigging Manual

Pipeline pigging is an vital technique used within the oil and gas domain to monitor pipelines. This fundamental procedure requires launching designed gadgets, named pigs, into the pipeline. Pigs are constructed to traverse the stretch of the pipeline, completing various assignments.

Different sorts of pigs are ready, each tailored for a distinct purpose. Common employments of pipeline pigging cover examination for defects, purging, and pipe lining.

- Pros of Pipeline Pigging

- Repercussions on Operational Efficiency

- Kinds of Pipeline Pigs

Trusted Sanitation by means of Pigging Methods

Pigging frameworks grant a solid answer for preserving sanitation inside channels. These frameworks incorporate dedicated tools that navigate through the pipe infrastructure, effectively cleaning layers. The practice is especially effective for domains that insist on rigorous cleanliness standards. Pigging systems contribute a cost-saving and prompt approach for disinfecting equipment, minimizing the exposure of taint.

Opting for Pigging Apparatus for Particular Expectations

Pigging hardware acts a vital role in effective pipeline activity. When favoring pigging apparatus, it is essential to consider the distinct requests of your task. This consists of considering criteria such as pipeline diameter, flow flux, product form, and maintenance goals.

Diverse pigging options are ready, each built for distinct purposes. Namely, some pigs are crafted for auditing, while others are deployed for extracting debris or distributing product quantities.

Additionally, pigging instruments elements should be agreeable with the moved fluid.

It is commonly ideal to liaise with a professional in pigging practices to confirm that you opt for the most effective instrument for your unique specifications.

Integrated Pipeline Solutions - A Benefit-Focused Approach

Tubular maintenance systems offer a large collection of pros for realms relying on lines. By seamlessly cleansing and surveying pipe interiors, pigging systems raise operational capability and lower maintenance outlays.

A primary asset of pigging systems is their potential to remove deposits such as calcium buildup, debris, and corrosion remnants. This consistent hygiene ensures smooth pipeline circulation and obviates costly downtime.

As well, pigging systems can be employed to assess the health of pipelines, discovering possible flaws before they develop into severe concerns. This anticipatory plan enables to extend the lifespan of pipelines and reduce overall maintenance expenses.

Supporting Hygiene in Pigging Tasks

Piggy rearing operations significantly count on appropriate hygiene procedures to limit the distribution of harmful agents. Implementing rigorous hygiene protocols ensures a clean setting for pigs, whereby produces heightened health outcomes and capability.

Frequent cleaning and disinfection of sites is necessary to limit the volume of harmful infectious agents. Systematic discard management likewise fulfills a fundamental part in securing hygiene.

Besides, pigging products {workers