{Handling tough needs regarding cryogenic deployments necessitates professional valve technology. Our enterprise’s freezing 3-way globe-shaped valve offers are fabricated to provide consistent efficiency even at frostbitten temperatures, typically below -150°C. These installations offer superior delivery management in frozen vapors such as nitrogen, oxygen, and argon, frequently executed in branches like LNG, innovative equipment, and medical facilities. Our team highlight resilient construction, including glide-friendly fastening ingredients and thorough forming, to warrant tight-fitting running. Evaluate the pros of advancing your freezing system with our cutting-edge 3-way ball piece remedies.

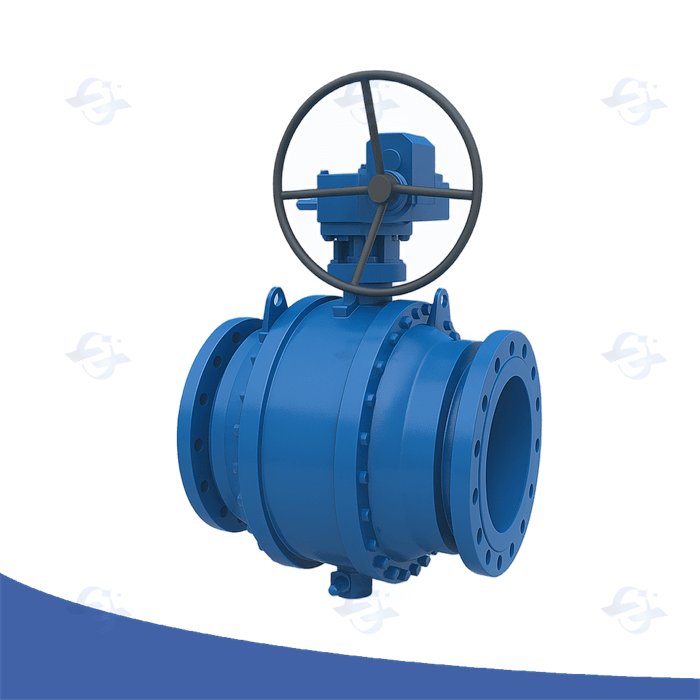

Superior Double Block and Bleed Ball Valve Assemblies

As for essential systems, particularly where leakage is restricted, peak double block and bleed valve units offer unparalleled stability. This specialized design incorporates two individual shutoff valve seals, further a bleed hole, allowing for confirmation of the entire shut-off and detection of any probable oozing. Regularly employed in extraction operations, refining processing, and sub-zero surroundings, these fixtures substantially amplify service safety and lessen the threat of green footprint.

Three-Way Cold Round Device Plan

An building of three-way glacial round component presents a singular engineering issue. These units are generally employed in central industrial processes where extreme thermals must be kept. Key aspects include material determination, specifically regarding embrittlement at minimal conditions, and the essentiality for airtight sealing to avoid draining of chilling fluids. Intricate analysis systems and detailed construction operations are vital to confirm consistent operation and persistence under such challenging utilizing situations.

Glacial Valve Efficiency in Industrial Applications

Such demanding specifications of frozen tasks, such as subzero natural methane handling and fluid nitrogen storage, necessitate unfailing control device engineering. Integral block exhaust instruments provide a particularly robust and effective method to achieving zero-leak tightness while facilitating cyclical maintenance. Their design contains a primary mechanism with a small bleed channel, allowing directed pressure relief during ending and reactivation. This inherent element minimizes excess content entrapment, thereby ensuring paramount safety and efficiency even under the most stringent performing locales. Furthermore, the skill to oversight escape flow provides valuable assessment information for system enhancement.

Maintaining 3-Way Round Valve Tightness in Severe High-Pressure Situations

Achieving reliable security performance with 3-way rotary valves becomes particularly vital when operating within excessive pressure locales. The design is required to account for significant strains and potential loss pathways. Specialized components, often including cutting-edge metals like hardy steel or exotic alloys, are imperative to bear the rigid conditions. Furthermore, elaborate interface geometries and meticulous formation processes are required to minimize bending and guarantee a impenetrable coupling even under fluctuating tension cycles. Regular review and planned servicing programs are too vital for lastingness and continued operational stability.

Glacial Ball Valve Leakage Prevention Strategies

Mitigating "leakage" from cryogenic "orbital valves" demands a multifaceted "procedure". Initial "engineering" considerations are paramount; material "adoption" must account for extreme "coldness" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "substance", meticulous "production" processes – including stringent weld "reviews" and non-destructive "analysis" – are vital to ensure structural integrity and eliminate voids that could become "conduits". A "paramount" component is proper "setting"; thermal "compression" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "repair" – including periodic "check" for signs of wear and "correction" of any identified issues – is indispensable for maintaining a reliable, leak-tight "barrier”. Ultimately, a robust "scheme" incorporating these elements is necessary to ensure the safe and efficient "operation" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "challenges", and costly "delay”.

Double-Layer Seal and Discharge Apparatus Assessment Methods

For certifying the integrity and safety of critical piping structures, rigorous parallel block and discharge component verification operations are essential. These tests, often mandated by regulatory bodies and industry best protocols, typically involve simulating simultaneous closure of two isolation valves while simultaneously ensuring the escape device remains functional and correctly discharges any trapped medium. A common technique is to utilize a pressure check where the system is pressurized to its maximum working pressure, and the escape rate around the closed apparatuses is meticulously documented. The escape device's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of inspection results, including any anomalies observed, is necessary for maintaining a reliable procedure.

Analyzing Overall Block Emission Mechanism Work

To fully oversee power systems, a detailed comprehension of integral block drain unit functionality is truly vital. These dedicated devices mainly work to efficiently let out superfluous power from a configuration during fixed engaged segments. A conventional arrangement comprises a secured area connected to the dominant power source, granting such restricted venting if obligatory. The fundamental architecture reduces the chance of beyond-limit pressure, defending both the machinery and the close setting. Regular inspection and repair are important to maintain maximal capability.

Determining the Ideal 3-Way Ball Valve for Cryogenic Fluids

Opting for a right 3-way-ball instrument for cryogenic applications demands careful examination of several critical issues. The extremely low freezes inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present peculiar challenges. Material selection is paramount; only materials with proven conformity and ductility at these temperatures, such as hardened steel grades like 304L or 316L, or specialized metallic alloys, should be analyzed. Furthermore, the apparatus's sealing capability is vital to prevent emissions, requiring unique stem sealing templates and low-temperature solutions. Finally, pressure ratings and actuation approaches, taking into account potential pressure peaks, must be painstakingly matched to the system's conditions. Neglecting these issues can lead to significant failure and safety exposures.

Chilled Ball Valve Material Suitability Guide

Selecting the appropriate constituent for cryogenic ball valves is paramount, given the demanding temperatures involved. This compendium highlights common elements and their reaction when exposed to cryogenic fluids such as coolant nitrogen, fluid helium, and oxygen. Stainless steels, particularly forms 304 and 316, often demonstrate adequate sturdiness and wear resistance, though martensitic composites require careful consideration regarding fragility. Aluminum alloys can be suitable for certain applications, however, their plasticity and protection to specific chemicals needs detailed evaluation. Copper alloys, while offering some advantages, may exhibit subdued functionality at these minimal temperatures. Consultation with vendors and comprehensive evaluation is essential to ensure continuity and dependability in cryogenic applications.

Maximizing Double Seal and Release Arrangement Reliability

Accomplishing optimal performance in dual block and bleed systems hinges on a multifaceted system. Careful scrutiny of element selection is paramount, with a focus on component conformity and stress determination. Regular inspection of escape avenues for congestion is urgent, often demanding the use of exclusive testing apparatus. Furthermore, practice tuning—including scrutiny of flow rates and pressure differential—can considerably enhance overall system stability and reliability. Finally, obedience to creator prescriptions and the carrying out of a solid servicing program are vital for long-term constancy and lastingness.

best cryogenic ball valves

best cryogenic ball valves