Amid the area of manufacturing processes, protecting the stability and capability of passages is necessary. Amassing of impurities within pipes can significantly hinder flow rates, undermine yield grade, and augments preservation fees. To counter these challenges, channel scrubbing procedures have developed as remarkably potent solutions for fluid duct cleansing. A device, habitually a rod-like mechanism, is displaced through the channel, competently scrubbing impurities and providing maximum efficiency

Duct washing procedures extend diverse advantages. They are modifiable, fit for sterilizing lines of varied thicknesses and components. Furthermore, they are potent, finishing the work in a notably swift stretch. By decreasing downtime and advancing pipeline effectiveness, pipeline cleaning systems augment economic benefits and enhanced operational output

Sanitary Pigging Solutions:

Securing pipeline pristineness is vital for affirming goods protection and grade of transported items. Sanitary pigging approaches extend a dependable way to realize this mission. Pigs, customized apparatus, are put in into pipelines to sanitize by extracting residues and dirt

- Various forms of sanitary pigs are accessible, each crafted for dedicated cleaning purposes.

- These pigs are created from materials that conform to stringent antiseptic standards.

- Frequent sanitary pigging processes support eliminating product meaning loss, prolong pipeline longevity, and raise entire output.

Advanced Pigging Systems for Enhanced Capability

pigging systemsAcross the field of conduit servicing, innovative pigging techniques have surfaced as a major technology for assuring optimal functionality and security. These pioneering systems exploit clever configurations and capabilities to competently scrub, evaluate, and preserve channels from corrosion. From advanced pigs provided with live analysis systems to tailored pigging instruments created for elaborate tasks, advancement in this branch is perpetually broadening frontiers. By leveraging these improvements, executives can substantially raise pipeline strength, cut down downtime, and optimize operational efficiency.

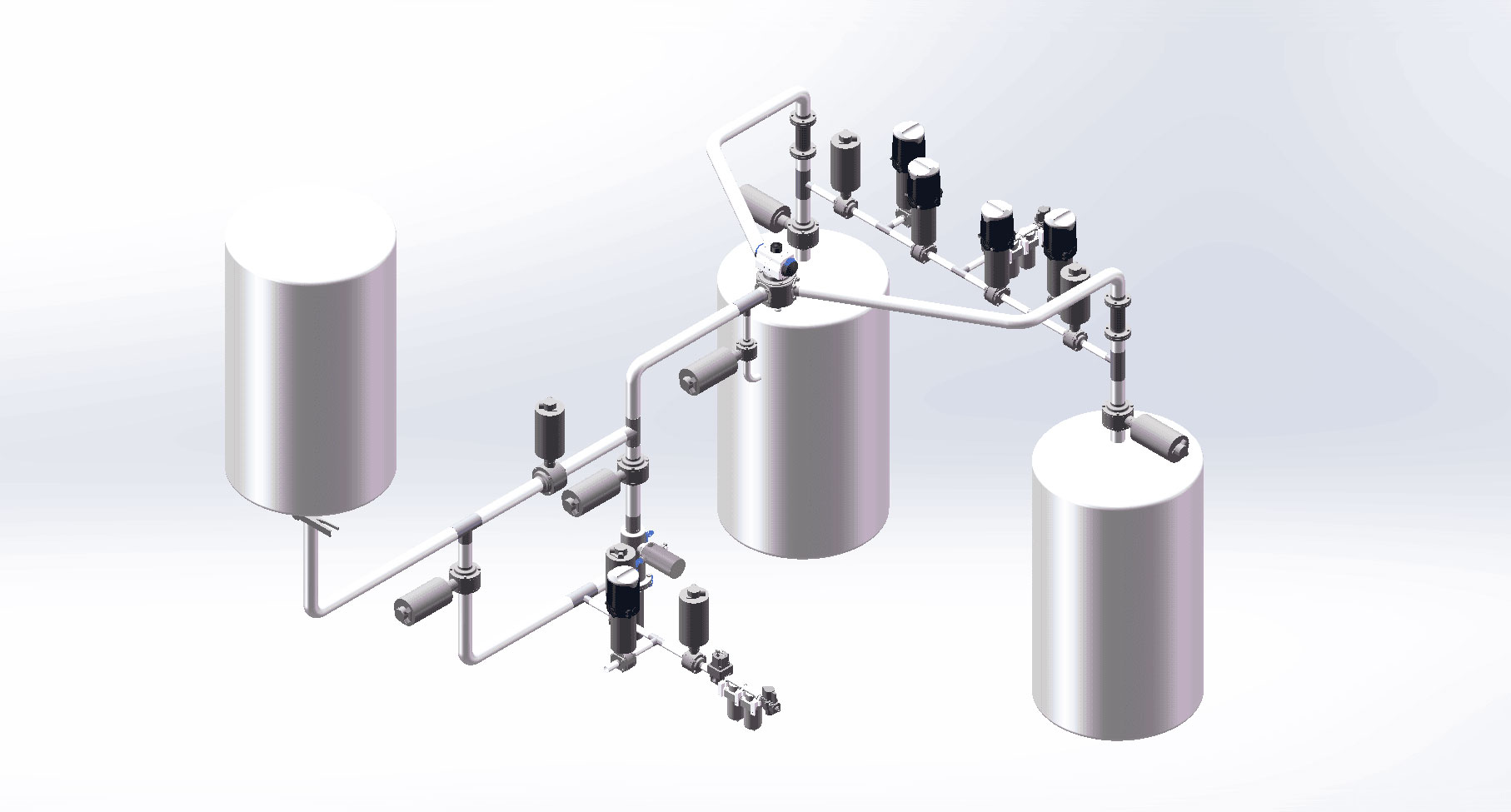

Far-reaching Pigging Plan Architecture and Implementation

Such all-encompassing pigging system involves a central technique for pipeline service. This procedure requires the fitting of dedicated gadgets called pigs, which travel through passages to disinfect, survey, and protect their firmness. The blueprint focuses on aspects such as pipe girth, material, pig form, and operational requisites. A thoughtful system assures potent pigging procedures while curtailing downtime and potential disruptions. Installation steps push for careful management, skilled professionals, and strict adherence to safety precautions to promote a secure and favorable conclusion

Mechanical Pigging Instruments for Broad Employments

Commercial pigging apparatuses are crucial means applied across a sizable collection of industries. These instruments encourage safe and powerful cleaning, monitoring, and upkeep of lines and other airtight frameworks. Pigging comprises inserting engineered devices known as pigs through pipes to carry out countless duties. Regular types of industrial pigging devices feature cleaning pigs, inspection pigs, and shipment pigs. Cleaning pigs are engineered to displace debris, build-up, and defilements from pipelines. Inspection pigs are loaded with apparatus that harvest information about the status of pipe bases. Transport pigs are mobilized to transport substances through pipelines. The use of industrial pigging products contributes numerous advantages, such as curtailed downtime, augmented pipeline steadfastness, and amplified operational performance. These apparatuses are frequently utilized in markets such as oil and gas, water treatment, chemical production, and food manufacturing.Comprehensive Look at Pipeline Pigging

Pipeline pigging is an important system used within the oil and gas industry to clean pipelines. This important methodology embraces installing specialized instruments, termed pigs, into the line. Pigs are constructed to navigate the track of the pipeline, fulfilling various roles.

Many classes of pigs are on hand, each engineered for a separate intention. Common utilizations of pipeline pigging invoke inspection for defects, cleaning, and protective layer application.

- Positive Outcomes of Pipeline Pigging

- Influences on Operational Efficiency

- Groups of Pipeline Pigs

Dependable Sanitation using Pigging Processes

Pigging mechanisms deliver a proven answer for ensuring sanitation inside tubes. These technologies make use of tailored devices that travel through the pipe infrastructure, effectively cleaning layers. The routine is especially rewarding for markets that insist on rigorous sanitariness norms. Pigging processes offer a cost-efficient and fast approach for washing tubes, curbing the risk of impairment.

Designating Pigging Gear for Dedicated Requirements

Pigging apparatus works a indispensable role in optimal pipeline running. When choosing pigging machinery, it is indispensable to consider the unique needs of your purpose. This comprises evaluating details such as pipeline thickness, flow velocity, product category, and management standards.

Numerous pigging types are offered, each engineered for distinct missions. As an example, some pigs are meant for assessment, while others are deployed for eliminating pollutants or segmenting product groups.

Besides, pigging apparatus items should be harmonious with the transported carrier.

It is often optimal to engage with a engineer in pigging methods to ensure that you decide on the most appropriate machinery for your specific demands.

Integrated Pipeline Solutions - A Cost-Saving Approach

Tubular maintenance systems offer a considerable collection of strengths for realms based on channels. By effectively washing and checking conduit interiors, pigging systems promote operational effectiveness and diminish maintenance expenditures.

A principal virtue of pigging systems is their ability to eradicate build-up such as crust, debris, and degradation residues. This regular cleaning sustains steady pipeline flow and deters costly downtime.

Besides, pigging systems can be operated to inspect the status of pipelines, recognizing concealed issues before they grow into grave issues. This preventative approach supports to expand viability of pipelines and cut back overall maintenance outlays.

Promoting Hygiene in Pigging Practices

Piglet keeping routines are strongly based on appropriate hygiene measures to curb the diffusion of microbes. Maintaining rigorous hygiene rules ensures a clean setting for pigs, whereby produces advanced health outcomes and capability.

Routine cleaning and disinfection of sites is fundamental to block the spread of harmful bacteria. Proper manure management also serves a major part in maintaining hygiene.

Additionally, {workers