In every case elaborate extended tube layout and creation, collaborating with genuine specialists is crucial. These competent patterned tube generation specialists possess a detailed awareness of temperature control principles, component characteristics, and the cutting-edge processes for creating high-performance heat exchangers. They attend to everything from design inception and sample production to extensive assembly and strict testing. Selecting the right patterned pipe creation authority can positively affect the operation and service life of your equipment.

Advanced Serrated Tubing

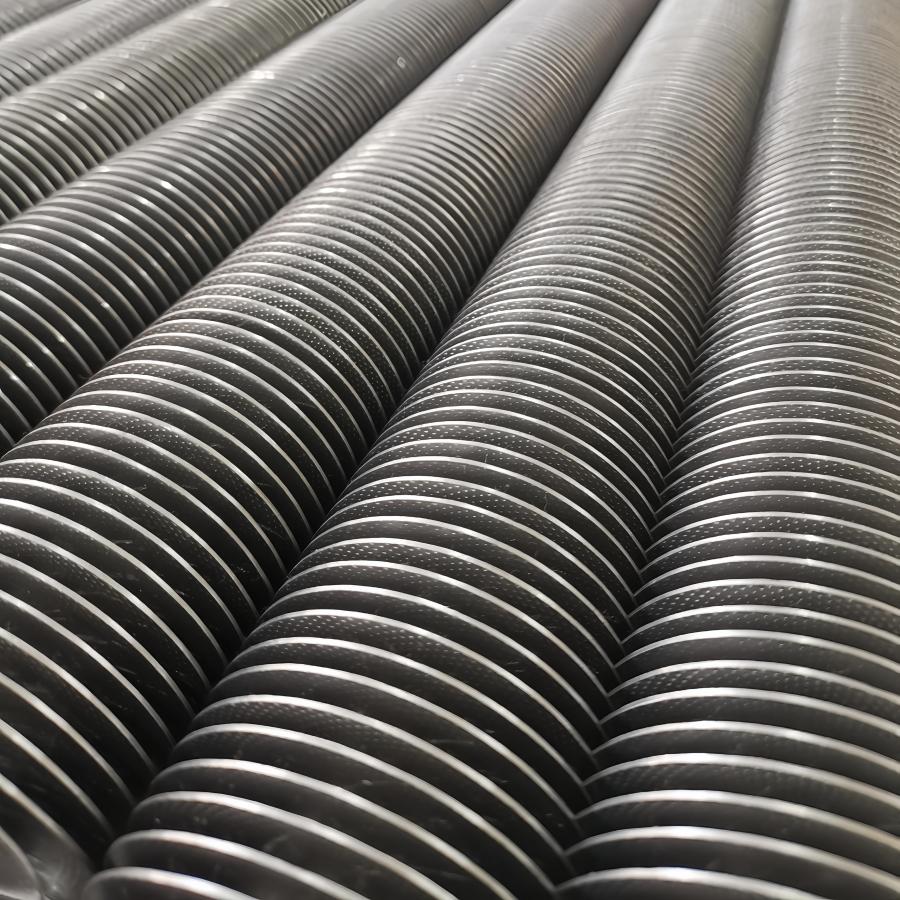

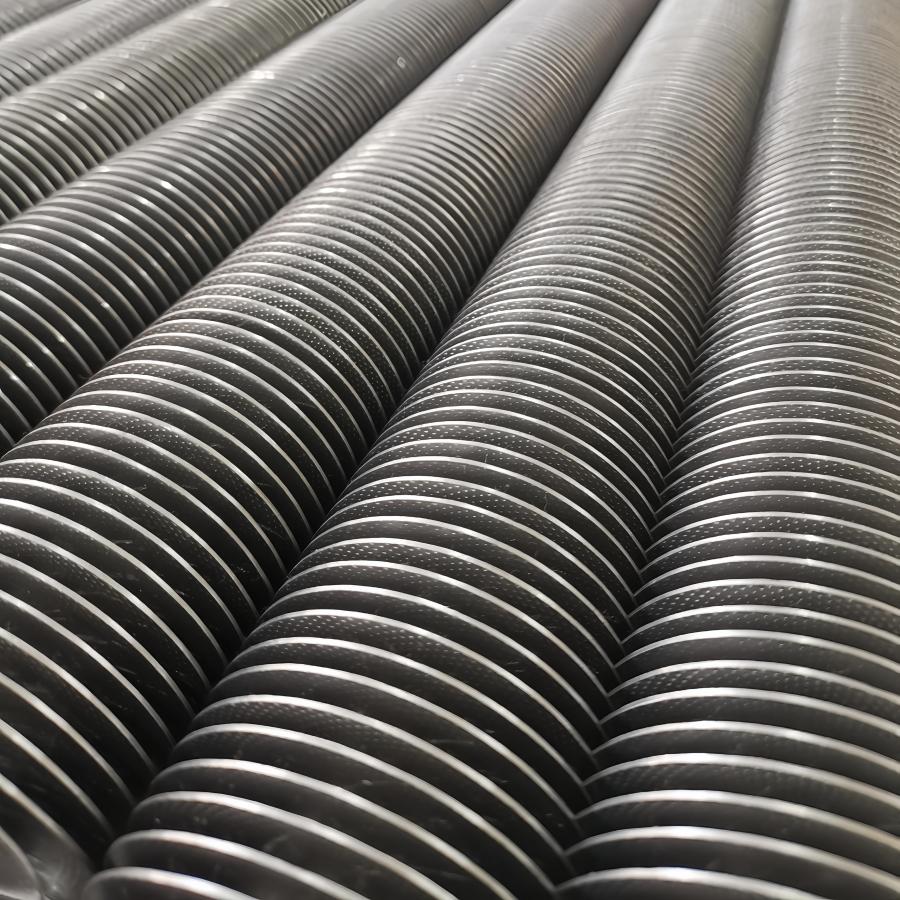

Modern engineering systems frequently demand distinctly efficient power exchange, and superior finned hollow bodies are necessary to achieving this. These elements utilize precisely designed edge geometries, regularly employing sophisticated configurations to expand the area available for caloric transfer. Building methods may entail forming, paired by accurate fin modeling and from time to time a tailored surface layering to further optimize capability. Opting for the proper finned channel composition is contingent on the distinct operating circumstances, especially media features, heat grades, and stress intensities.

Bespoke Improved Copper-alloy Ducting Answers

Tackling challenging heat management necessities? Our expert team creates custom-finned copper pipe arrangements precisely within your application. We exploit advanced manufacturing techniques and correct calculations to optimize thermal conduction efficiency. Whether you're in the industrial sector, or need top-tier cooling regarding a challenging process, our extended copper lines can produce superior output. We assess factors such as fluid passage rates, ambient temperatures, and physical constraints designed for construct a truly unique and productive solution.

Technicians in Grooved Aluminum Tube Systems

For several years, we've been dedicated to providing unparalleled expertise in ribbed aluminum pipe design, assembly, and placement. As leading specialists, we offer a comprehensive collection of services, catering to a vast spectrum of industries, including climate control, energy creation, and reaction processing. Our group of highly skilled engineers displays a solid understanding of heat migration principles and constituent science, ensuring that every endeavor we undertake delivers optimal output and stability. We cherish ourselves on delivering bespoke options that precisely fulfill our clients’ unique requirements. Whether you require metal radiator repair, refurbishment, or a total system layout, our commitment to quality remains unwavering. Communicate with us today to consider your customized problems.

Augmented Tube Fabrication and Guidance Provision

Maximizing warmth movement efficiency is paramount in countless realms, and that's where specialized improved tube fabrication and consulting offerings truly shine. We furnish comprehensive tools encompassing everything from initial design to full-scale deployment. Our personnel of experienced technicians leverage advanced imitation techniques and domain best techniques to design personalized augmented tube modules for a wide array of demanding environments. Whether you're seeking to increase efficiency, decrease energy costs, or confront specific operational concerns, our finned tube expertise delivers maximum results. We additionally offer steady inspection facilities to confirm ongoing operational integrity.

Progressive Precision Finned Tube Assembly

The requisitions of modern heat transfer systems are driving a change towards highly refined finned tube techniques. Traditionally, elementary fin layouts were adequate, but now applications in electrical devices and manufacturing processing necessitate severely tight tolerances and elaborate geometries. This involves exact fabricating of fins directly onto the tube frame, often utilizing sophisticated frosty operation equipment to achieve the desired radiator altitude, interval, and outline. Over and above, the constituent selection plays a important function, with bespoke fusions frequently exploited to increase thermal performance while maintaining formative solidity. Benchmark testing systems are also indispensable to maintain consistent grooved tube standard.

Enhanced Copper Pipe for Heat Exchangers

Cutting-edge heat dispersion systems frequently incorporate finned copper duct as a crucial constituent in heat exchangers. The embedding of fins, usually made from aluminum, significantly augments the surface space available for heat distribution, leading to a superior efficient heat trade. These grooved copper pipelines are widely found in applications ranging from factory processes, such as temperature control machinery, to family HVAC systems. The prime thermal conductivity of copper, combined with the augmented surface area provided by the fins, produces in a notably effective method for supervising finned copper pipe heat. Different fin patterns, including even and wavy, offer varying degrees of performance enhancement depending on the specialized application’s conditions.

Cutting-edge heat dispersion systems frequently incorporate finned copper duct as a crucial constituent in heat exchangers. The embedding of fins, usually made from aluminum, significantly augments the surface space available for heat distribution, leading to a superior efficient heat trade. These grooved copper pipelines are widely found in applications ranging from factory processes, such as temperature control machinery, to family HVAC systems. The prime thermal conductivity of copper, combined with the augmented surface area provided by the fins, produces in a notably effective method for supervising finned copper pipe heat. Different fin patterns, including even and wavy, offer varying degrees of performance enhancement depending on the specialized application’s conditions.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum enhanced tubes offer a compelling combination of low-weight construction and remarkable output, making them ideal for a diverse range of factory heat transfer operations. Their unique formation—featuring aluminum textures attached to the tube covering—significantly augments the heat exchange power without adding substantial weight. This translates to minimized energy costs and improved overall process steadiness. Consequently, these tubes are frequently appointed in HVAC setups, refrigeration, and other heat conducting processes where minimizing mass and maximizing power transfer are paramount points.

Finned Tube Fabric Options: Bronze & Al

Once electing finned tube material, engineers frequently scrutinize copper and aluminum. Copper offers exceptional degradation withstand and superior energy conduction, making it appropriate for applications where efficient heat distribution is paramount, such as in cooling units systems. However, copper's increased rate and anticipated for galvanic corrosion with other metals can be limiting restrictions. Conversely, aluminum provides a significantly lower expense and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Perfecting Heat Dispersion with Finned Hollow Bodies

The output of heat apparatus frequently hinges on the design and realization of finned conduits. These structures significantly augment the surface area available for heat dispersion, allowing for a much greater rejection of heat compared to simple, unfinned sections. The refinement process involves a complex interplay of factors, including fin form – such as fin height, spacing, and size – as well as the substance of both the fins and the root tubing themselves. Careful consideration of the medium flow characteristics, whether it's air or a substance, is also paramount to ensure that the heat extraction isn’t restricted by boundary layer effects or uneven distribution of the working gas. Ultimately, a well-designed finned pipe array delivers a meaningful improvement in overall thermal effectiveness within a given space.

Robust Finned Tube Assemblies for Production Applications

Accommodating the needs of demanding production environments necessitates reliable heat flow devices. Our finned tube packages are engineered for exceptional functionality, providing reliable heat transmission in a range of applications, from chemical processing to air-conditioning control. Constructed from premium materials and featuring advanced wear endurance techniques, these units minimize restoration downtime and maximize operational output. The exclusive fin arrangement promotes increased heat distribution, even under demanding operating circumstances.