dedicated corrugated container producer why choose reliable packaging container producers over standard suppliers?

Discover the sophisticated craft of corrugated container construction by means of this detailed resource. This presentation reveals the vital processes for changing plain sheets into robust containers that cover products during shipment. Covering grooving, printing, and packaging, we'll uncover the intricacies of this vital industry.

- Explore the assorted kinds of corrugated packaging and their particular purposes.

- Survey fresh inventions in container fabrication.

- Gain insight into the ecological footprint and sustainable alternatives.

Whether a pupil, technician, or industry aficionado, this tutorial furnishes critical awareness of the shifting carton creation domain.

Generating Models with Corrugated Board

Corrugated board, usually ignored as elementary packing substance, functions as a multipurpose crafting medium. Its tough attributes support the fabrication of creative formations and configurations, spanning useful organizers to fanciful embellishments. With a little ingenuity, you can transform this common material into something extraordinary.

Discover the infinite potentials of corrugated paperboard art via:

- Exploring numerous methods like clipping, folding, and stacking

- Using recycled content for an environmentally sound method

- Unveiling your art to excite others

Due to its low cost, availability, and adaptability, corrugated fiberboard suits hobbyists at every age and ability level. Discover your creative potential and let your imagination take flight with this unassuming substance.

The Combination of Functionality and Flair in Corrugated Box Design

Corrugated box production portrays a thrilling synthesis of technical knowledge and creative design. It outperforms typical crafting; it prioritizes producing a defensive enclosure that shields goods throughout delivery while also making a enduring mark on patrons.

A knowledgeable developer perceives the subtle traits of corrugated board, optimizing its thickness, flute type, and configuration to meet specific requirements of each commodity.

- Similarly, beauty considerations are fundamental.

- A skillfully constructed carton appears promptly noticeable on racks, grabbing the notice of intended consumers.

- In essence, carton design balances safeguarding and attractiveness.

Satisfying Market: Increasing Your Packaging Output

When your business is booming and orders are surging, it's critical to ensure you have the capacity to meet customer demand. Expanding packaging fabrication might guarantee efficient operations and copyright credible reputation.

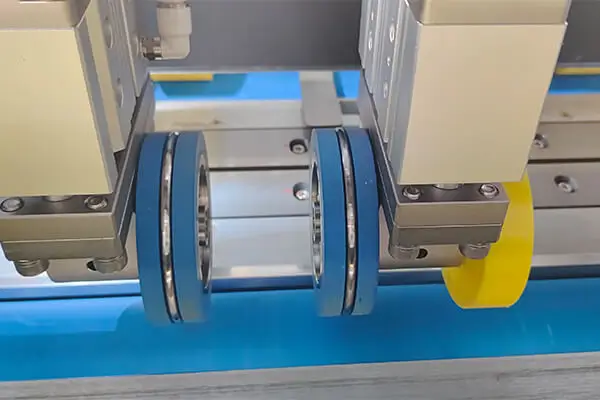

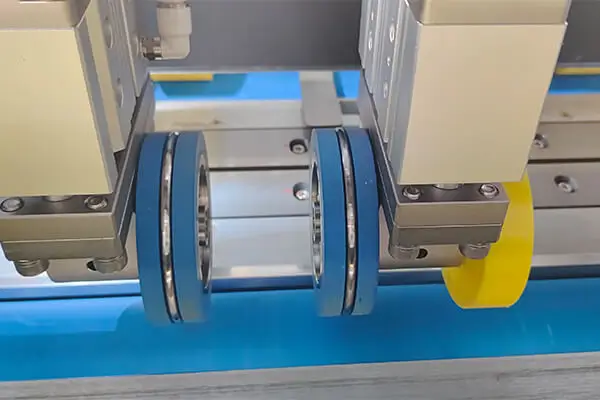

First of all, inspect your manufacturing setup. Examine available tools and personnel to locate potential blockages or zones needing enhancement. Afterward, investigate approaches for boosting production capability. Reflect on obtaining updated technology or refining current gear to raise efficiency.

Consider that boosting volume is subordinate to enhancing full production line. Employ agile production models to cut waste and maximize input use. Upgrade workflows, mechanize habitual tasks, and prioritize worker education to assemble a strong crew.

At last, establish solid rapport with distributors to assure regular input streams. Adopting these measures, you can effectively enhance carton assembly and satisfy mounting market demands.

Advancements in Corrugated Technology

The container industry relentlessly advances, powered by hopes for green, efficient, and groundbreaking means. Corrugated packaging board, a reliable substance for long, enjoys renaissance powered by original innovations. From strong structures to smart additions, corrugated pulpboard embraces forthcoming advancements. Companies research innovative approaches to improve container capabilities, using green components and operations. The upshot is a swell of inventive packaging projects modifying the industry backdrop.

These breakthroughs confront significant problems faced by firms, such as cutting waste and enhancing delivery networks. End-users likewise enjoy these advancements, with packaging that is more durable and more manageable. The prospect for corrugation is optimistic, brimming with opportunities for eco-friendly and streamlined packaging solutions.

Green Corrugated Cartons: Responsible Options

Corrugated containers represent a vital aspect of present-day supply networks. Commonly fabricated with fiber, these cases bear major effects on surroundings. Even so, heightened appreciation for eco-conscious strategies involves producing parcel goods. Luckily, fresh ideas are at hand to raise environmental responsibility of these cases.

A significant point covers incorporating repurposed fiber. Through exploiting processing or end-user scraps, the call for pristine inputs lowers, maintaining forests and ecological reserves.

Additionally, companies devote resources to green fabrication methods. This involves enhancing power usage and minimizing refuse across distribution networks. End-users can engage by adopting cartons validated for sustainability. Search for seals such as FSC or SFI that attest to sustainable sourcing and manufacturing.

By implementing these approaches, we secure packaging as a crucial market element while lowering environmental effects.

Assuring High Quality in Packaging Fabrication

Reaching top efficiency in carton manufacturing depends on thorough inspection protocols. Opening with raw material selection and closing with product scrutiny, each action requires steady attention. Stringent protocols are implemented throughout the manufacturing process to guarantee that each box meets the highest specifications.

- Checking base materials for faults, robustness, and sameness is necessary to precluding ensuing complications.

- Adhering precise dimensions and tolerances during cutting and forming ensures boxes are structurally sound and compatible for their intended use.

- Frequent analysis of printing ensures bold visuals and clear wording

- Adopting computerized evaluation tools boosts effectiveness and fidelity in assessment methods

By stressing rigorous checks during manufacturing, producers offer packages that are sturdy and eye-catching. Such attention to detail appeases consumer desires and fortifies brand credibility.

Carton Printing: Identity and Influence

Corrugated box printing is a vital aspect of brand awareness. As purchasers perceive your goods, the container acts as a major means for delivering impression. A professionally composed print on packaging can fascinate buyers, display brand traits, and raise purchase intentions.

Also, container labeling supplies diverse selections to individualize your boxes. From vibrant colors to unique designs, you can reflect your brand's spirit through the structure of the box itself.

Ultimately, corrugated box printing is more than just a functional necessity – it's a powerful means to strengthen your brand presence and connect with your audience.

From Basic Ingredients to Final Output: The Corrugated Box Procedure

The manufacturing of a corrugated box is a fascinating process that transforms simple raw materials into a vital shipping and packaging solution. The process initiates by acquiring pulp, often sourced from reused stock. Next, pulp transforms into segments of corrugated carton board, featuring a waved middle layer sandwiched between two flat liners.

These panels are carefully shaped per exact requirements, then joined with dedicated equipment to form the intended carton outline. Glues serve a key function in bonding pieces firmly, providing a sturdy and resilient configuration.

In conclusion, containers experience detailed testing measures to verify durability and alignment with trade regulations.

Arising from unassuming starts, the parcel becomes a dynamic packaging marvel, suitable to preserve broad merchandise during transport.

International Packaging Sector: Developments and Potentials

The global corrugated box market is experiencing a corrugated box maker period of growth. This lively industry is motivated by expanding client needs for shipment. Essential elements include advancement of online marketplace and desire for eco-conscious packaging